Application of Computer Vision in the Industrial Sector

Inventory management is a key process for all industrial companies, but the inventory process is both time-consuming and error-prone. Mistakes can be very costly, and it is highly undesirable to store more raw materials or fully completed and ready-to-ship products than are required at any given time. On the other hand, any shortfall in elements that make up a product may leave customer orders unfulfilled on time. In a warehouse which stores, for example, 10,000,000 items with an average value of $10, the loss of 0.1% of these items represents a cost of $100,000. The per annum cost of such a loss may run into millions of dollars. An automated object-counting system based on computer vision (CV) could speed up the process, reduce errors and lower costs.

Why is Inventory Management so complex?

There are many complexities to the art of inventory management, including the following factors:

- Range - the variety of stock keeping units (SKUs) to be tracked

- Accessibility - objects may be placed on high shelves in warehouses, out of reach and perhaps out of direct sight of workers

- Human error - objects may be miscounted or misrecorded in tracking systems

- Time management - taking an inventory of SKUs at the optimal frequency

These problems can be solved using an automated object counting system which is based on CV. For such a system to be genuinely useful, it must display a high degree of accuracy. An appropriately designed and trained CV application can then significantly reduce the possibility of mistakes and the time taken to execute the process.

An Automated Object Counting System

Digica developed an object counting system based on CV that is both highly accurate and easily customisable. For example, the system is able to detect, classify and count objects by class when they are located on a pallet. The initial system was designed to count crates of bottles.

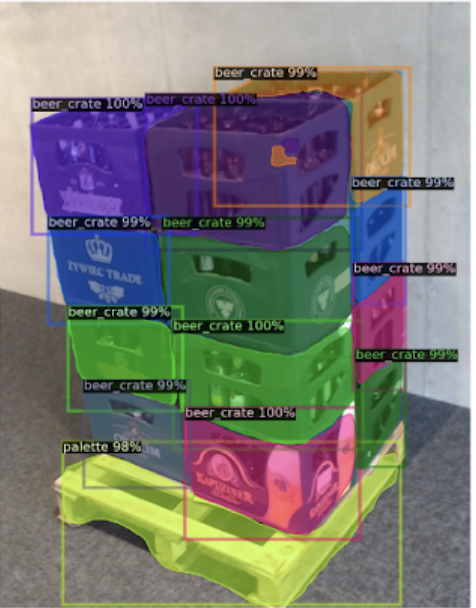

Example of detected crates when stacked on a pallet

A practical system deployed in a warehouse must be able to cope with a range of inconsistencies in the incoming data. It is unlikely that pallets are always placed in exactly the same locations or are always oriented in the same way. In the example above, all of the crates are detected in spite of the fact that the visible regions of the crates are not consistent. Crates are also recognised from both front and side views.

This system is clearly well suited for use with the CCTV systems which are typically installed in warehouse environments. However, the technology could be adapted to run on automated vehicles or drones, which are devices that often run an embedded operating system that is capable of running Machine Learning (ML) applications. This could lead to a fully automated inventory process in which humans are responsible only for controlling the work of the machines.

Note that this system does not need SKU-specific barcodes or QR codes, which simplifies the deployment of the system in existing warehouses. Therefore, existing processes do not require any modification, and it is not necessary to place objects so that any existing barcode is kept visible.

A Customisable System

This computer vision system is highly customisable. At its core is a pre-trained neural network which can be readily retrained to support a specific target environment. The possibilities are almost limitless! The system could be used for purposes such as:

- Detecting and counting small objects, such as screws or nails on a conveyor belt

- Detecting boxes on pallets during packing for the purposes of quality control prior to shipping

- Aggregating information about certain objects in large physical areas, such as shipping ports for example, by carrying out an inventory on shipping containers

Integration with a wider range of systems is also possible. As the system provides real-time inventory data, it is possible to automatically make orders for resources for which stocks are running low. Integration with other ML systems could allow predictive ordering to optimise prices. Sensor-fusion techniques can also be easily applied, by combining a CCTV signal with IR cameras for certain objects that present variable temperature spectra. Such a system makes it possible to monitor objects, such as batteries, which are at risk of overheating.

This system was trained using a combination of publicly-available and self-generated data. Whilst this works well in a demonstration environment, training on target environment data will give a higher level of accuracy. Such target environment data may not be available, but the problem lends itself well to the use of synthetic data for training purposes. Furthermore, such data can be easily integrated into the training pipeline.

The Digica team has completed a large range of projects which make use of computer vision. With the advent of Industry 4.0, the time has come to give to industries that rely on Inventory Management the technology upgrade that they need to stay competitive!