Computer Vision and AI at the Edge with the Leading Thermal Camera Provider and the Major Toy Brick Manufacturer

1 year ago

As the pace of artificial intelligence innovation accelerates, we’re seeing AI and computer vision go from science fiction tropes to enabling highly efficient and compelling applications. This integration is particularly potent at the edge, where devices locally perform analytics and data processing, rather than relying on centralized servers.

This blog post details two compelling real-world examples that showcase the power of CV plus AI at the edge: training thermal imaging cameras in drones to recognize multiple object types and correcting visual defects in the manufacturing lines of the leading construction brick toy company.

Training systems on a FLIR thermal imaging camera

One key player in the transformation is deploying sophisticated imaging systems, such as FLIR cameras.

What does FLIR stand for in cameras?

FLIR stands for Forward Looking InfraRed. FLIR is a thermal imaging camera designed to capture thermal radiation, which is emitted from all objects that produce or interact with heat. A thermal imaging camera creates pictures from heat, not visible light, enabling it to operate in various lighting conditions, including complete darkness.

What is the use of a FLIR camera?

FLIR cameras are extensively used for surveillance, night vision, and scientific applications. They are invaluable tools for detecting people, machinery, or materials that exhibit temperature differences with their surroundings. In industrial contexts, they help in monitoring equipment to predict failures before they occur by detecting overheating parts.

How can FLIR cameras be used for image detection?

The unique ability to capture thermal data opens doors for image detection tasks beyond the limitations of the visible spectrum. A standard camera relies on reflected light, rendering it ineffective in low-light conditions. A thermal camera however, can detect heat signatures regardless of ambient light, making it ideal for scenarios where traditional cameras struggle.

Training FLIR cameras in drones

Drones equipped with FLIR thermal cameras are revolutionizing industries by performing remote inspections, aerial surveillance, and large-scale monitoring.

Digica recently built a comprehensive system for training FLIR detectors in military-grade drones. They created, trained, and validated datasets from over 2 million images, to deliver highly accurate drone, people, vehicle, and airplane detectors. Working with petabytes of 3D data, classifiers for over 1,000 object classes were developed, including drones, vehicles, airplanes, civilians, and people in uniform.

Digica: Drone training data for FLIR cameras

Digica: Aircraft training data for FLIR cameras

Digica: People training data for FLIR cameras

The resulting comprehensive training pipelines now enable drones to be deployed in multiple projects, far from their original military purpose. Similarly, with the new camera control capabilities, subsequent thermal camera detector training will be far simpler and will require fewer data science-orientated personnel, resulting in a massive reduction in time and cost.

By leveraging the power of AI and CV at the edge in a thermal imaging camera, we’re pushing the boundaries of what's possible in diverse fields. These real-world examples showcase the immense potential for enhanced image detection, improved quality control, and ultimately, a new era of intelligent automation.

Visual Defects in Toy Production Lines

In traditional production lines it often falls on human operators to identify visual defects. However, in fast-paced environments like a toy manufacturer’s production line, this approach is prone to fatigue, inconsistency, and limitations in speed. By deploying a defect detection system using AI plus CV at the edge, quality control was revolutionized.

What are visual defects on a production line?

Visual defects in a product line refer to any anomalies or irregularities observed in the products that deviate from the intended design or quality standards. In toy brick manufacturing, this commonly occurs as color inconsistencies, sizing errors, and defects like cracks, scratches, and dents.

Digica: Input -> CNN -> output (heatmap)

What are the criteria for a visual inspection?

The criteria for a visual inspection typically involve parameters like alignment, color accuracy, dimensions, and the absence of physical blemishes. Automated systems are trained to compare each unit against a predefined standard or template to ensure consistency and quality across the production batch.

How to identify visual defects and correct them on a product line

In advanced manufacturing setups like toy brick production lines, visual defects are identified using high-speed, high-resolution cameras integrated with AI-driven image processing software.

Digica trained computer vision models to recognize three different types of printing errors. The output took the form of heat maps with the pixel probability of belonging to the erroneous area. The threshold was established as to whether a brick was accepted or rejected.

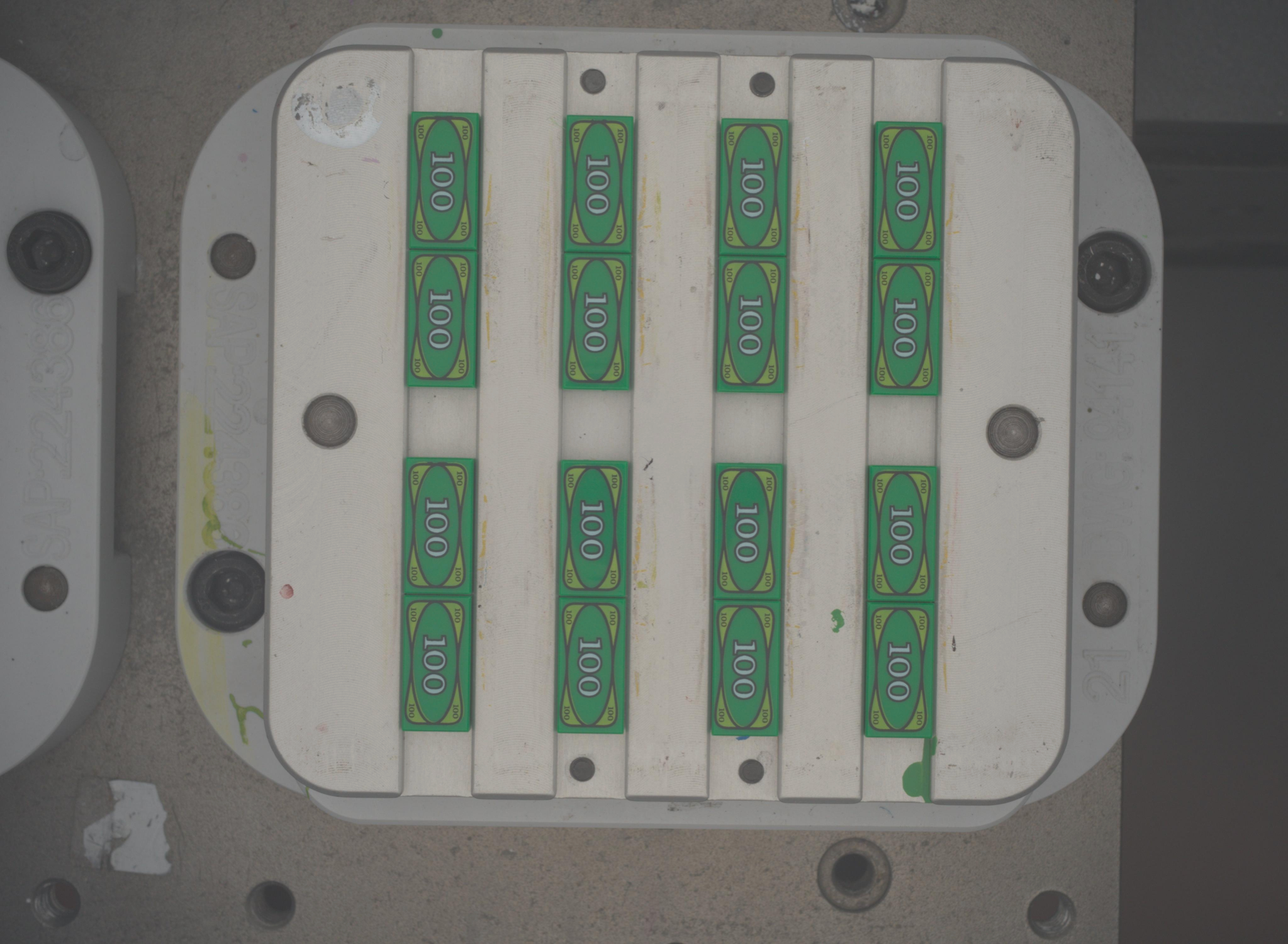

Digica: The jig in a factory

Technologies used included:

- PyTorch + PyTorch Lightning + Albumentations + OpenCV - for training Smudge and Offset models

- Makesense.ai - for making the annotations

- OpenCV + Scikit learn - for creating the color error procedure

- Docker + FastAPI - to implement the API server

- Plotly - for the interactive plots

The solution was specifically trained on toy bricks and was able to see the difference in gradient dying, as well as the printing of those blocks, which wasn't detectable on today's standard production lines.

Using small AI models on the edge there was no need to send image data to the cloud for processing. By simply running on camera analytics, such as inference, it was possible to detect defects in real time. Small models running on cameras were able to flag defective pieces and remove them from the production line.

The application of thermal cameras and AI in tasks like training systems and quality control on production lines exemplifies the potent synergy between advanced imaging technologies and edge AI. By leveraging these technologies, industries are not only able to enhance operational efficiency but also push the boundaries of what can be achieved in terms of automation and precision in manufacturing and beyond.